|

|

|

|

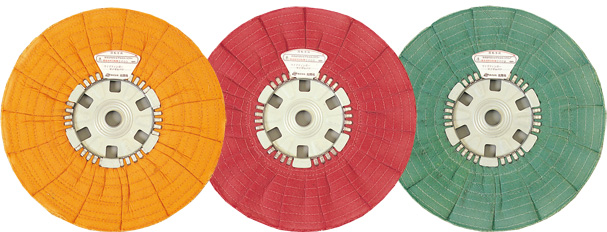

A-Type

Golden treatment |

B-Type

Big Red treatment |

C-Type

Green treatment |

|

Wide Finger Sisal Buff is the buff with sisal cloth inserted in cotton cloths, then molded in loose pleats,

fixed with a clinch ring in center infolding and machine-sewn with moderate intervals.

Wide Finger Sisal Buff is suitable for cutting /

cut & coloring of steel and stainless steel due to uniformity and moderate hardness when contacting with workpiece.

3 types according to stitching method. All buffs are treated.

A-Type : Standard (Sewing on spiral)

B-Type : 1 stitch (1cm from clinch ring)

C-Type : 2 stitches (1cm from clinch ring and middle part between periphery and clinch ring)

*Thickness : approx. 18mm

| *Use with special flanges (Sold separately) |

|

|

|

|

|

|

|

To make the most of the ideal cutting feature of sisal cloth, this buff is woven with spcial thread and bias-cut.

Due to great cutting and cooling effect, high-speed poliching is endured and burning on the surface prevented.

Widely used for cutting of roll workpiece, cutting workpiece, pressed workpiece of steel / stainless steel and casting. etc.

| * |

Bias sisal buffs are all treated.

Standard treatment is "First" which is colorless.

Thickness : approx. 13mm

|

|

|

| *Use with special flanges (Sold separately) |

|

|

|

|

|

|

|

|

|

Unit Sisal Buff is the buff with bias-cut sisal cloth inserted in cotton cloths and machine-sewn units are fixed with clinch ring radially.

Due to good conformity with contoured polishing surface & cooling effect, suitable for cutting / cut & coloring in steel, stainless steel and aluminum diecast. |

|

| *Use with special flanges (Sold separately) |

|

|

|

|

|

|

|

|

|

Unit Cord Sisal Buff is the buff with sisal twine inserted in cotton cloths and machine-sewn units are fixed with clinch ring radially.

This buff with black treatment has great polishing performance and long life with excellent hardness and polishing compounds retention.

Suitable for cutting of steel / stainless steel as well as polishing with high pressure and high load.

|

|

| *Use with special flanges (Sold separately) |

|

|

|

|

|

|

|

|

|

All-purpose sisal buff with moderate hardness which has uniformity on wide polishing surface and conformity to irregular surface.

Use by taking advantage of the characteristics of treated & untreated.

|

|

*Thickness : approx. 17mm

| *Use with special flanges (Sold separately) |

|

|

|

|

|

|

|

|

|

Bias-cut sisal cloth are inserted between cotton cloths.

This buff has regular wave pleats unlike our Open Sisal Buff which has irregular pleats (waves).

Buff emphasized on cutting performance by providing thickness and moderate hardness to buff.

Designed for less space between buffs in layerd use, less section line appearance is the major characteristics. |

|

| < Recommended treatment > |

| Treatment |

Characteristics |

| Super Yellow |

Relatively hard treatment foe steel / stainless steel |

| Super Green |

Soft treatment with conformability for non-ferrous metal |

|

|

|

*Thickness : approx. 35 mm

| *Use with special flanges (Sold separately) |

|

|

|

|

|

|

|

| Wave Sisal Buff |

|

Proper stiffness and flexibility provide great conformability to workpiece.

Regular-pleat-structure prevents section lines to appear to the minimum in piled-up use.

Due to great retention of polishing compounds, polishing performance will last resulting in uniform polishing surface. |

|

| < Flange-Separate-Type > |

| unit : mm |

Outside

diameter |

Inside

diameter |

Bore |

| 300 |

125 |

25.4, 31.8, 38.1,

50.8, 76.2 |

| 350 |

|

|

|

| < Flange-Integrated-Type > |

| unit : mm |

Outside

diameter |

Inside

diameter |

Bore |

| 250 |

100 |

25.4 |

| 350 |

135 |

|

|

|

*Thickness : approx. 17mm

| *Use with special flanges (Sold separately) |

|

|

|

|

|

|

|

|

|

| Cord sisal buff is a buff with less hardness and less cutting power.

Suitable for polishing ditch and irregular surface same as that of common sanding brush.

May be used for the finishing of a special deluster. |

|

| *Use with special flanges (Sold separately) |

|

|

|

|

|

|

|

|

|

| Die-cut cotton cloth sheets and sisal cloth sheets are layered and spirally stitched from the center to the outer edge.

By layering sisal cloth and cotton cloth, fray of sisal fibre can be prevented and also buff’s ability of holding buffing compound can be enhanced.

As this type of buff is thin and very hard, it is suitable for rough polishing and middle finishing of small objects and narrow parts.

There are 6-ply type and 4-ply type. In this type of buff, ply number means number of sisal sheets. |

|

*Thickness : approx. 12 mm (6-ply)

*Thickness : approx. 8 mm (4-ply) |

|

|

|

|

|